Open Day in NTS!

On May 24th, from 2:30 pm to 4:30 pm, we will open the doors of our Lallio headquarter to students graduating in mechanics, mechatronics and mechanical ITS, on a visit to our production departments and offices.

The day will start by welcoming all students and making an introduction to the world of advanced manufacturing work and how in our company is realized for the sectors served.

We will continue with the visit to the NTS production spaces, guided by the department managers.

Then, during a shared moment, we will tell the professional path of some of our youngest colleagues working in different divisions within NTS: from Research and Development, to the design of the mould equipment and to the responsible of the industrialization.

This open day aims to create a bridge of communication and orientation between the world of school and work, offering new knowledge and opportunities to young students and, at the same time, attracting new talents that can support us in our business growth.

The appointment is for Wednesday, May 24th, from 14:30 to 16:30, in NTS in Lallio (BG), in via Morletta, 10/12.

To participate you need to register by filling in the form at this link: https://forms.office.com/Pages/ResponsePage.aspx?id=Kq-q-TfEYUCx_quK4Rf6vnTAV52QmKRDtNGg-i1UQN1UM0lPTU45JxXYxTYkRQUlJFVVUlV4u

May began with a great gift in NTS: on the day of Workers’ Day we had the pleasure of hosting in our spaces the Bishop of the diocese of Bergamo, Monsignor Francesco Beschi, who officiated, in front of more than 200 people, The Labor Day Mass.

The emotion was great and tangible, not only for the lively and heartfelt participation of workers with their families, partners, collaborators and institutional figures, but also for the touching words of the Bishop during the homily, that gave a spiritual completeness to the moment lived together.

The celebration was an opportunity to talk about what motivates us every day in our work, the importance that dignity and the balance between private and professional life in a working context like ours, aimed at improving individual and collective well-being through initiatives that go beyond the simple daily task.

In fact, in NTS we believe we must take care of our future today in order to build the tomorrow we want, giving opportunities for growth and education to young people, establishing a social dialogue with employees, in order to create cohesion and passion for the work we do every day. And all this is possible only by giving meaning to the work, which goes beyond the individual project, product or service, but becomes the object of realization both personal and professional satisfaction.

This is the most important value we talked about during the celebration of May 1st: being able to express our being and completeness as human also through work, a work that more favors our precious individuality.

It was a special moment to crown our journey because we understood that, “sowing in time genuine and strong values”, we have gathered esteem and recognition from the community. We will continue to strive for growth and improvement driven by our values for a long time to come! – Marco Manzoni, CEO of NTS

NTS was chosen by the Diocese of Bergamo as a workplace to host Monsignor Francesco Beschi on the occasion of the diocesan celebration of the St. Mass for and with the workers.

So, on May, 1st at 15:30 you are invited to our headquarters in Lallio to live and share this opportunity, for us very significant and valuable.

It will not only be a celebratory Eucharistic passage, but also a moment to pay homage to the culture of “doing”, which is an integral part of our being and our productive fabric.

The Bishops’ message entitled «Youth and Work to Nourish Hope» gives an opportunity for reflection and touches on the themes of employment, school, the solidarity economy and the dignity of every person. The St. Mass in memory of St. Giuseppe will be an opportunity to emphasize the importance of work, as a part of our life, and to reflect on how essential it is to give value to young people to build the future.

At the end of the celebration there will be an Open Day where you can visit and learn about our company.

In order to guarantee you more organization, we ask you to confirm your participation at the e-mail address ufficiolavoro@curia.bergamo.it. Reservations will be taken subject to availability.

NTS colleagues can confirm their presence with their family and friends here: https://forms.office.com/e/US2kQKNwiH

Read also the article of the Eco of Bergamo: https://www.ecodibergamo.it/stories/Hinterland/primo-maggio-la-messa-del-vescovo-in-unazienda-di-lallio_1472216_11/?utm_campaign=socialbeat-distribution-intelligence&utm_source=Facebook&utm_medium=Socialbeat&fbclid=IwAR1daF5sCJJkcE9a4ntr2oGgX9GGZjPQskr55GR4gXL0O1SCiZStcj0XapU

New project in progress, new goals coming soon

We all know very well how companies are engaged on a daily basis to offer their products and services in an increasingly sustainable and competitive way, keeping up with the times and taking care of the planet.

At NTS we like facing new challenges and reaching new horizons: this is why we decided to take a new path that will lead us towards a greener and cutting-edge reality.

Since December 2022 we are active members, together with 30 other European partners, of the DeremCo project (De & Remanufacturing for Circular Economy Investments in the Composite Industry), financed through the Interregional Innovation Investment (I3) Instrument under the European Regional Development Fund (ERDF).

With us there are partners from Italy, Finland, Austria, Spain, Slovenia, Belgium and Portugal.

The topic of this project, which will last until November 2025, is fibro-reinforced plastics, structural components of a wide range of consumer goods and industrial goods, the management of which post-Use in accordance with circular economy principles remains a significant challenge.

The aim of the project is to find and to propose a systematic, cross-sectoral and demand-oriented solution that falls within the production and consumption model typical of the circular economy and that allows a re-use, economically advantageous, of compound materials and components in new high value-added products.

This solution is based on the interaction between technical and social ecosystems, both local and interregional, and aims to bring different benefits to the environment, industry, consumers and European society.

The sustainable and circular value chain will be transformed into a so-called “pull” system, where the demands and specifications on the materials and components to be reused will be transferred directly from the demand side in terms of the quality and functions of the high value-added products reusing the material.

We will be leaders and end users of the case study “Demonstration of automotive frames produced with r-BMC material from recycling of end-of-life wind turbines and production and end-of-life waste products in BMC/SMC”. More precisely, we will share with different partners our internal experties on equipment production, stamping process and materials: our ultimate goal is to propose to our customers a renewed concept of sustainability linked to thermoset materials.

Other important objectives will be to encourage industrial adoption within local ecosystems, to promote and reduce the risks of the future industrial adoption of the project through private investments and to sensitize consumers towards a more conscious and sustainable behavior in perfect Plastic Bee style, just as we are at NTS!

The De & Remanufacturing for Circular Economy Investments in the Composite Industry project, identified with Call I3-2021-INV1 and Topic I3-2021-INV1-MANU, has a total duration of three years from December 2022 to November 2025 and was founded by the European Union and directly financed by the European Regional Development Fund (ERDF) with Gran Agreement No. 101084037.

The total cost of the project will be € 12,603,930.83, while the total amount of European funding is € 8,822,751.58.

On 10 October from 14:30 to 17:30 there will be the meeting Strategic Community on Advanced Polymers organized by the Association Fabbrica Intelligente Lombardia (AFIL) of which NTS is a member since this year.

On 10 October from 14:30 to 17:30 there will be the meeting Strategic Community on Advanced Polymers organized by the Association Fabbrica Intelligente Lombardia (AFIL) of which NTS is a member since this year.

The central topic of this meeting will be intelligent polymers and this will be, for us at NTS, an opportunity to meet partner companies and universities with which to develop new projects in the field of advanced polymers and related applications.

The meeting will begin with the presentation of the stakeholders present and will continue with a brainstorming on the Manifestation of interest of the Lombardy Region to show the progress and define the specific themes and projects to be integrated into the proposal. After that we will open the doors of our reality and personally accompany the participants to the event on a tour of our company.

Promoting these events, for us, means deepening the themes of technological development at the base of the company evolution, as well as becoming part of an important network that also allows us to be part of a direct dialogue with the Lombardy Region and with the projects of the Strategic Development Plan of the European Community.

The event is exceptionally open to all, with a view to the inclusivity of the Event of Interest, and participation is free, but subject to the capacity of the room and, for this, you must register online through the appropriate form.

To learn more about the event visit AFIL https://www.afil.it/ or feel free to contact us. For further information, please write to Elena Mossali at segreteria@afil.it.

Entrepreneurship, education, recycling, sustainability, composite polymer, school furniture, were the key words of our participation in the program “Enterprise in Action” (https://www.impresainazione.it/) conducted by Prof. Armando Persico and the organization JA Italia to stimulate the entrepreneurship of students.

Entrepreneurship, education, recycling, sustainability, composite polymer, school furniture, were the key words of our participation in the program “Enterprise in Action” (https://www.impresainazione.it/) conducted by Prof. Armando Persico and the organization JA Italia to stimulate the entrepreneurship of students.

The goal was to help students successfully manage mini-companies and then present the final results to the public.

As NTS, as Fabio Cortinovis and Marco Manzoni, we actively participated in this initiative as Dream Coach, helping and stimulating the students of the Salesian Institute of Treviglio (BG).

In particular, we participated in the initial phases of concept work with the students, who, thanks to their curiosity and perspicacity together with the preparation and passion of their professors, did everything else by creating the project entitled “Tavolità”.

We are happy to have taken part in the project, especially because the boys of the Institute of the Salesians of Treviglio have crowned the splendid result by winning the first prize of € 4,000, after presenting a few days ago their mini-company in front of 200 people in the UniBg classroom of Sant’Agostino and leaving the jury and all the people present speechless.

On 17 May there will be the Lombardy Regional competition, while later they will also have access to the national finals in Milan of the Festival of Youth Entrepreneurship 2022.

We can help them realize this great dream of theirs by watching and sharing the video about the presentation of their project “Tavolità” at this link: https//vimeo.com/708567660.

The NTS Social Academy is proposing new topics on which to discuss and discuss in full NTS style.

The NTS Social Academy is proposing new topics on which to discuss and discuss in full NTS style.

On 29 April we talked about a conflict of positivity: every day we live in conflicts, small or large, sometimes even with ourselves, but how many do we turn into positive energy?

Knowing how to recognize and manage it is very important to build your serenity. With the criminologist Luca Villa we deepened the theme, catapulting it into our daily lives.

Friday, May 20 will be the turn of another meeting. The appointment will always be in Natta room, at 17.30: here we will be guided by the expert Maurizio Naibo, private banker, who will teach us how to protect their assets, how to choose the most suitable investments for yourself and your family and how you can save effectively.

The goal will be to acquire an “ABC” of financial education to become more aware and more and more proponents of their own life choices.

To register: https://docs.google.com/forms/d/e/1FAIpQLSdRT6I5CszwOPZKv6saQsAj6ZnJDSJUV07goQcGNPtXguB5jg/viewform

In these moments of uncertainty and strong economic changes, what is the only certainty? Don’t give up and look beyond.

For us, it means pursuing our slogan “beyond moulding” with respect to what we do in everyday life.

From 15 March we are officially members of the cluster AFIL – Associazione Fabrica Intelligente Lombardia, specifically we will be part of the “Advanced Polymer Community”.

For us, it means new opportunities.

Visit the AFIL website www.afil.it to discover more.

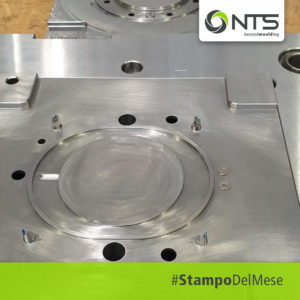

This month’s steel mold has interchangeable dowels and in 2022 will allow the production of thousands of PPS technopolymer components for the hydrogen production system.

With the creation of this new steel mold we have achieved the goal of winning over a new customer in the world of hydrogen of which, for a guarantee of confidentiality, we cannot disclose further details.

With pleasure, however, we share the method by which NTS introduced itself in a promising “green hydrogen” sector in which billions of euros of European Union investments will lead to the 2030 decarbonisation goals.

It all started with an active reference from another customer of ours (automotive sector) satisfied with the “Tech” service of timely prototyping and technical consultancy on molding. Thanks to this reference, the new customer contacted us and after a first cognitive meeting in which we centered the expectations of technical and service competence, we started an NTS Tech approach based on the geometric study and mathematical simulation of molding of the product proposed by the customer who highlighted valuable characteristics unknown to the customer.

This generated technical and commercial trust up to the technical and technological need of the component in PPS polymeric material. So, with the customer, started a phase of co-design of geometries and tolerances up to conquer it also in the next phase: the confirmation of the order for the serial production of the component.

This new NTS Tech case in an innovative sector of hydrogen allowed the company to have the confirmation of how a modern approach oriented to active listening to the market with a healthy dose of organizational flexibility of internal skills can generate business opportunities for the whole company.

To find out more, you can contact our Sales Department or write to info@ntsmoulding.com

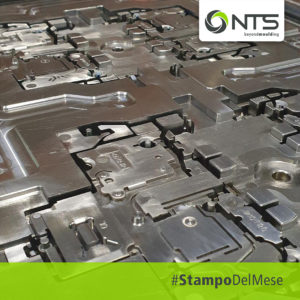

Here is the new 4-cavity hardened steel mold made in NTS for the electromechanical sector (energy management): it is now ready to produce the molding of millions of switches, in thermosetting resin 18% glass fiber, necessary to guarantee the safety of the electrical circuits of buildings around the world.

It was a simple block of steel that with the passion of 2.000 hours of work was transformed into a productive technological machine.

To find out more, you can contact our Sales Department or write to info@ntsmoulding.com