Fast

Manufacturing

Fast

Manufacturing

It is the new service provided by NTS Tech dedicated to short time production, from the single part in additive manufacturing in 48 hours until small series in 15 days through injection moulding.

Metal

Replacemenet

It is one of the services with a high added value we are proposing to the customers willing to innovate their product.

It is an exclusive consultancy and technical support service (integrated – if necessary – also by specific know-how of third parties, our partners) starting from the choice of the material to the new design of the part geometries with the customer, from prototyping till mould construction and mass production of the parts. NTS designs and creates the piece in composite material (glass fiber and resin) so resistant and performing that it can completely replace the corresponding material with a metallic matrix. This activity is always carried out considering sustainability and economic convenience as goal.

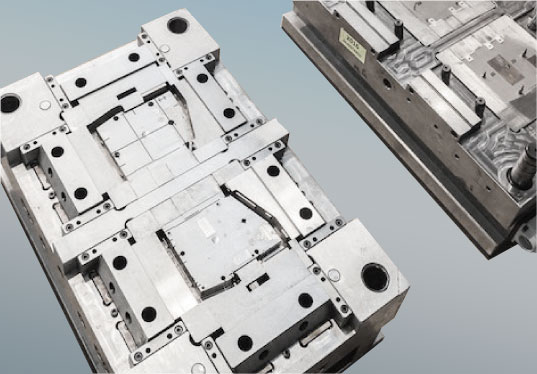

DESIGN AND CONSTRUCTION

OF CUSTOM MOULDS

From the design of the products to be made, our Technical Office develops, studies and constructs the mould for the customer.

Our moulds are made with cuttingedge machine tools that are also connected to robotic systems.

MOULDING

OF PLASTIC MATERIALS

After having carefully examined moulds, raw materials, product and process documentation, we transform thermoplastic, thermosetting (with glass fibre and carbon) resins and latest generation technopolymers.

High technology coordinated by an MES and Lean Thinking approach allow us to guarantee a quality finished product as well as respect the agreed timeframes.

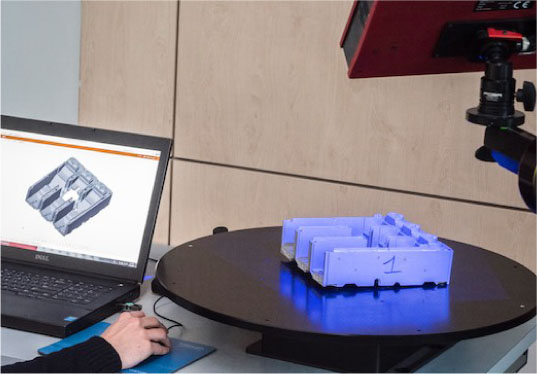

PRODUCT QUALITY

CONTROL

Each moulding activity is monitored by specific statistical quality tests. These tests also involve using optical inspection machines to make the necessary geometric verifications of the pieces produced.

INNOVATION AND SUSTAINABILITY,

FIRST OF ALL

In every production cycle we are committed to innovation and sustainability. The optimisation of processes, the careful selection of green-oriented suppliers, the continuous focus on quality and good daily practices are the foundations of our company policy.

Once a year we write an environmental report, setting ourselves increasingly ambitious goals: from the monitoring and reduction of energy consumption to the production of photovoltaic electricity and LED lighting of the departments.

ASSEMBLY

Automation and expert hands unite to create an accurate and monitored assembly service. Instruction through on-the-job training and mapped processes ensure that assembly activities are well organised and on schedule.