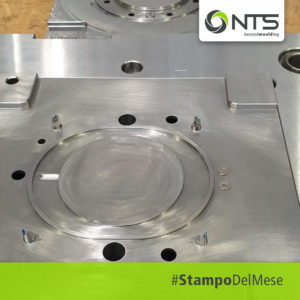

This month’s steel mold has interchangeable dowels and in 2022 will allow the production of thousands of PPS technopolymer components for the hydrogen production system.

With the creation of this new steel mold we have achieved the goal of winning over a new customer in the world of hydrogen of which, for a guarantee of confidentiality, we cannot disclose further details.

With pleasure, however, we share the method by which NTS introduced itself in a promising “green hydrogen” sector in which billions of euros of European Union investments will lead to the 2030 decarbonisation goals.

It all started with an active reference from another customer of ours (automotive sector) satisfied with the “Tech” service of timely prototyping and technical consultancy on molding. Thanks to this reference, the new customer contacted us and after a first cognitive meeting in which we centered the expectations of technical and service competence, we started an NTS Tech approach based on the geometric study and mathematical simulation of molding of the product proposed by the customer who highlighted valuable characteristics unknown to the customer.

This generated technical and commercial trust up to the technical and technological need of the component in PPS polymeric material. So, with the customer, started a phase of co-design of geometries and tolerances up to conquer it also in the next phase: the confirmation of the order for the serial production of the component.

This new NTS Tech case in an innovative sector of hydrogen allowed the company to have the confirmation of how a modern approach oriented to active listening to the market with a healthy dose of organizational flexibility of internal skills can generate business opportunities for the whole company.

To find out more, you can contact our Sales Department or write to info@ntsmoulding.com